- Main page

- Products

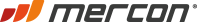

- Valves

- Control valves

- Control valves

-

The special plug design allows improving valve rangeability by reducing minimum controllable flow and plug erosion.

The high pressure recovery factor value compared with conventional contoured plug control valves ensure higher flow rates on compressible fluid service and reduces cavitation risk and effects on liquid service.

Together with the standard high capacity trim, low noise trims and double cage trims are available respectively for critical service on compressible fluids (gas and vapor) and for high differential pressures or for cavitating service where higher pressure recovery factor values are required. All versions have quick change trim.

Balanced Plug with Pilot execution allows to comply with IEC sealing class V up to 566°C for compressible fluids service. "Flow to close" configuration improves seat ring protection and increases seating force making this solution particularly reliable.

Contoured unbalanced plugs are available for dirty fluids service.

A special material configuration is available to comply with NACE MR0175 and MR0103 standards. VeGA control valves are usually equipped with Parcol diaphragm spring return pneumatic actuators 1-X-210 and 1-X-250 series (pneumatic cylinders 1-X-400 series for DN 16″ and over). Electrical or hydraulic actuators are also available on request.

Features

- nominal diameter: 1/2 to 24”

- nominal pressure: 10 to 100 bar

- medium temperature: -55 to 566°C

-

- Variable flow

- Process connection flange, welding ends, threaded

- Sensor / wetted parts material 316/316L, carbon steel, Duplex

- Seals graphite, PTFE, TA Luft, metal-to-metal

- Housing stainless steel, steel, cast iron

-

`

-

MERCON Valves Catalogue

1.2MB | POL

-

Parcol SIL3 Certificate

446kb | ENG

-

Parcol ISO 9001-2008 Certificate

641kb | ENG

-

Parcol TA-Luft Sealing pack Certificate

1.3MB | ENG

-

Parcol EAC Certificate RU

6.6MB | POL

-

Parcol PED Certificate Mod A1

191kb | ENG

-

Parcol PED Certificate Mod D

361kb | ENG

-

Parcol PED Certificate Mod H

88kb | ENG

-

Parcol 1-6940 Datasheet

5.6MB | ENG

-

Parcol Packings for control valves

2.2MB | ENG

-

Parcol Noise Manual

1.1MB | ENG

-

Parcol Handbook for Control Valve Sizing

1.5MB | ENG

-