- Main page

- Products

- Valves

- Control valves

- Pressure reducing and desuperheating stations (PRDS)

Approvals & certificates

-

PED

PED

-

CE

CE

-

NACE

NACE

-

EAC Ex

EAC Ex

-

SIL 3

SIL 3

-

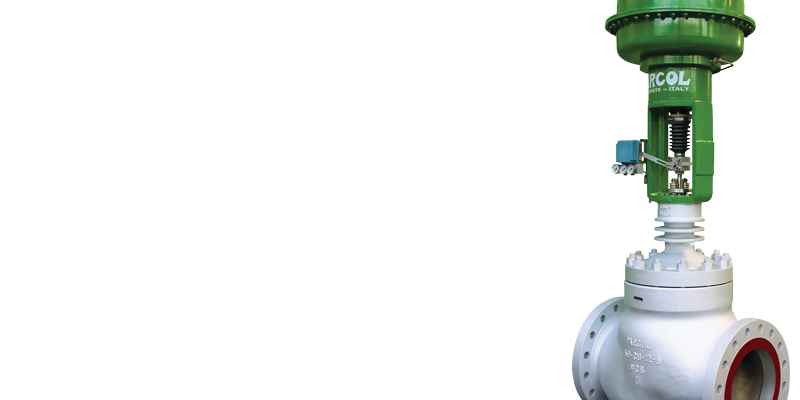

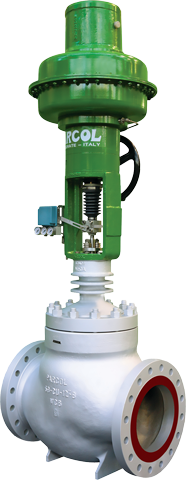

Parcol 1-5700 Pressure Reducing and Desuperheating stations (PRDS) represent the most universal and compact solution for pressure reduction and desuperheating of turbine by-pass lines, discharging both to intermediate or low pressure sections of power stations.

The spherical body shape design, together with the high quality of construction materials, allow a more uniform wall thickness than the conventional ones, fabricated by welding bodies, reducing P/T fatigue effects and improving welded joints quality.

The pressure reduction is mainly achieved through two stages: the first stage has the function to adjust the flow rate by means of a drilled cage trim, the second stage, designed with fixed throttling section, has the double function to generate a backpressure on the first stage by reducing fluid velocity and generated sound pressure level, and to convey the steam towards the injection chamber, at speed and distribution suitable to optimize the desuperheating process.

The second stage has also an absorbing function, acting as silencer towards the noise generated by the first stage. Such a function is remarkable in multi-cage figures, where the clearance between silencers is optimized to reduce noise frequencies between 1kHz to 4kHz, or when a Limiphon disk stack is installed as a silencer.

The desuperheating section, put immediately downstream the second stage, consists of the injection chamber complete with injection nozzles or a different Parcol desuperheater, to be selected according to operation conditions, plant lay-out and required process turn-down.

-

- Variable flow

- Sensor / wetted parts material 316/316L, carbon steel

- Seals graphite

-

`

-

MERCON Valves Catalogue

1.2MB | POL

-

Parcol SIL3 Certificate

446kb | ENG

-

Parcol ISO 9001-2008 Certificate

641kb | ENG

-

Parcol TA-Luft Sealing pack Certificate

1.3MB | ENG

-

Parcol EAC Certificate RU

6.6MB | POL

-

Parcol PED Certificate Mod A1

191kb | ENG

-

Parcol PED Certificate Mod D

361kb | ENG

-

Parcol PED Certificate Mod H

88kb | ENG

-

Parcol 3-5400 PED Certificate Mod B

4.4MB | ENG

-

Parcol 1-5700 Datasheet

2.9MB | ENG

-

Parcol Packings for control valves

2.2MB | ENG

-

Parcol 1-9000 reduction and desuperheating

979kb | ENG

-

Parcol Noise Manual

1.1MB | ENG

-

Parcol Handbook for Control Valve Sizing

1.5MB | ENG

-